Finland has the best bottle recycling system in the world, according to Marko Mäkinen, CEO of Pramia Plastic. The company received the National Entrepreneur Award in 2023 from the Federation of Finnish Enterprises for pioneering work in the circular economy sector.

Mäkinen’s state-of-the-art facility in western Finland recycles a million bottles a day. With 96 percent of plastic bottles in Finland returned to circulation, there’s plenty of supply to keep the plant churning.

Pramia Plastic was founded in 2012 as a subsidiary of the beverage manufacturer Pramia. “The first seven years were very difficult, but we started to get huge demand when the recycling boom took off in 2019,” says Mäkinen, whose firm exports its products around Europe. “Buyers were competing to buy our products.”

The factory converts bottles into plastic flake, plastic granulate and bottle blanks, also known as preforms. Each year Pramia also produces 50 million metres of recycled packing straps, which are widely used by sawmills and other businesses.

After winning the National Entrepreneur Award, Mäkinen said, “In Finland, we can produce 100-percent recycled plastic in large volumes. In many other countries, this isn’t possible due to poor-quality raw material.”

Following the roadmap

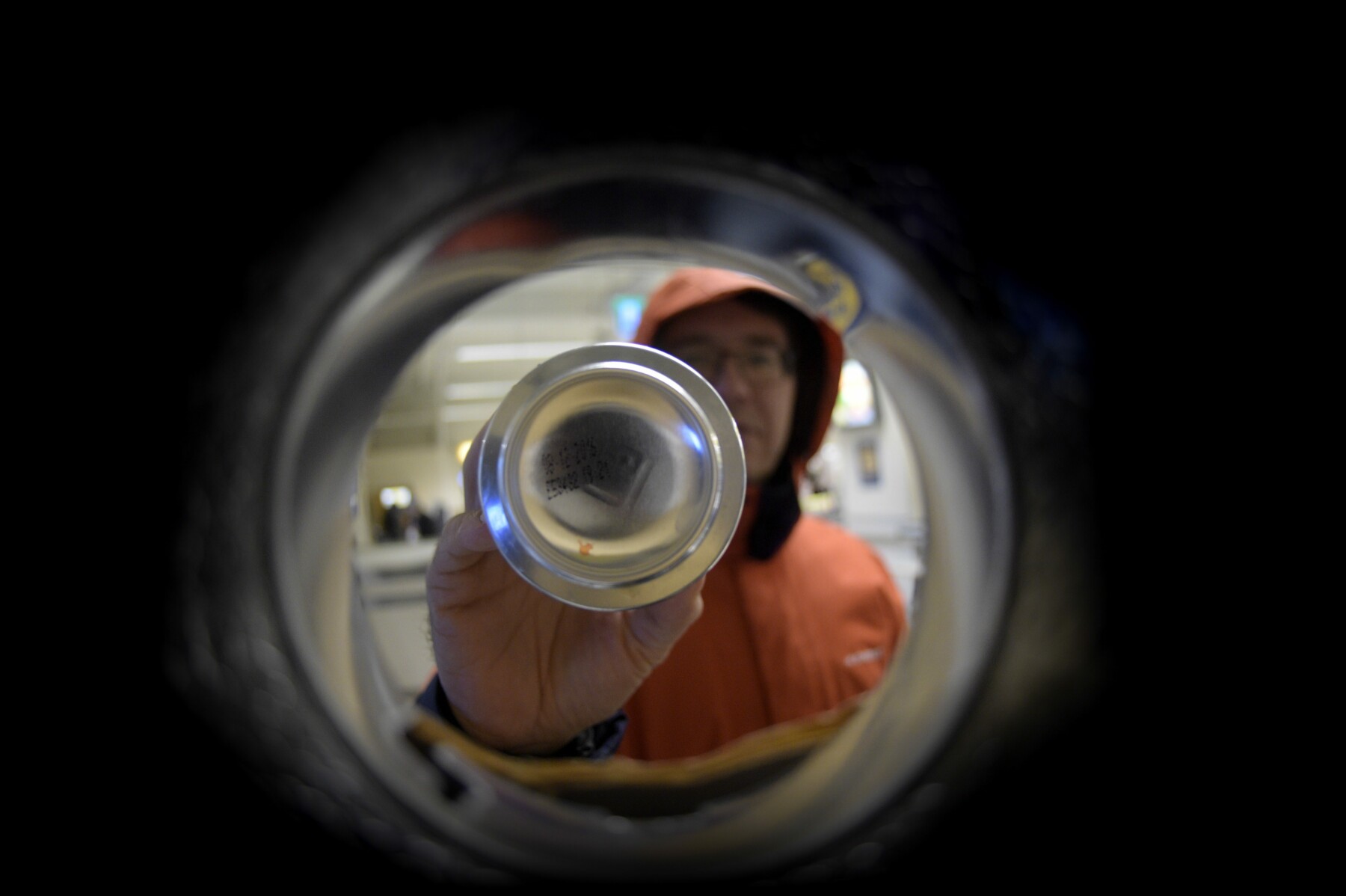

Inside view: A consumer feeds an empty bottle into a machine in order to get back the deposit money. For decades, Finland has had a near-total return rate for beverage containers.Photo: Martti Kainulainen/Lehtikuva

Despite the near-total return rate of plastic bottles, Finland still faces challenges with overall plastic recycling. The EU warned that Finland was at risk of falling short of the EU’s target, a recycling rate of 50 percent for plastic packaging by 2025.

That’s partly because a greater amount of corporate recyclable waste was being incinerated to generate power for industrial plants whose boilers were previously fired with wood imported from Russia.

The EU has also set a target of 55 percent by 2030. In Finland, officials and companies are working to stay on track with the Plastics Roadmap for Finland, a wide-ranging blueprint for a circular plastic economy by 2030.

Molecular-level recycling: the wave of the future

Production manager Ari Sillanpää has been one of the key people in ramping up WasteWise Group’s more efficient, chemical recycling methods.Photo: WasteWise Group

A larger proportion of packaging waste from households has been recycled since 2021, when a new law required each residential building with more than five apartments to provide a plastic collection bin. All businesses in urban areas must also separate plastic.

Plastic waste is usually recycled mechanically – by melting and granulating it – but Finnish firms have also come up with more efficient, chemical recycling methods. They break it down to the molecular level, making it possible to recycle nearly any type of plastics, including composites, and producing a circular raw material.

WasteWise Group opened the first such facility near Tampere in late 2023.

“Our method removes the need to incinerate plastic waste,” says Antti Åke, the firm’s CEO. “It produces pyrolysis oil, which replaces fossil fuels in the production of new plastics. WasteWise is the only Finnish company supplying pyrolysis oil, and market demand exceeds supply. We plan to increase our waste processing capacity to 24 kilotons by 2026 to direct more incinerated plastic waste streams toward chemical recycling.”

Doubling capacity

A bale of compressed plastic bottles crosses the threshold at Pramia Plastic’s recycling facility.Photo: Pramia Plastic

Mika Surakka is a trailblazer, having set up the first Finnish company to recycle mixed plastics into reusable products in 2000. He’s now managing director of Sumi, a nonprofit producer-responsibility organisation for packages, co-owned by 33 companies and 4,000 other corporate partners. He was honoured with the Environment Ministry’s first-ever Plastic Circular Economy Award in late 2023.

“Finland is still behind the EU target, but we’re working to get it closer,” says Surakka. “We need to motivate consumers to contribute more packages to our collection system.”

A study published by Sumi in May 2024 found that the collection rate for plastic packaging in Finland is roughly 45 percent, and that women are more active than men in sorting plastics.

Also in May, Sumi and the country’s biggest energy company, Fortum, announced the launch of a huge sorting plant for plastic packaging, set to begin operations in Riihimäki in early 2026.

“This will greatly improve the sorting and recycling rates, especially since we’re adding some of our own innovations,” says Surakka. The new plant will at least double the domestic capacity, sorting up to 50,000 tonnes of plastic packaging annually.

A win-win-win situation

These crushed bottle caps end up in pieces smaller than ten millimetres (0.4 inches) before becoming raw material for the injection moulding industry.Photo: Pramia Plastic

“We’ll then wash and granulate the plastic to produce recycled raw materials,” says Toni Ahtiainen, Fortum’s head of business line for plastics. “There’s market demand for high-quality customised materials made from recycled plastics.”

As Surakka sees it, recycling should pay for itself as a business without public funding.

“We need to find cost-efficient solutions and discuss with producers to find the right cost level. With packages, at least, it already works without public funding,” he says.

Merja Saarnilehto, a ministerial adviser at the Ministry of the Environment, agrees, saying, “In order to increase the recycling rate, we must find cost-effective solutions and possibly impose stricter requirements for separate collection, while investing more in new solutions.”

Recycling plastic is a win-win-win situation, says Antti Åke of WasteWise Group. “It creates additional value from domestic waste plastic streams, lowers reliance on fossil fuels, creates local business models and new jobs, removes the need to incinerate waste and lowers greenhouse gas emissions, while supporting the cradle-to-cradle mindset,” he says, envisaging a world where each product can be infinitely recycled or repurposed.

By Wif Stenger, September 2024