The modern clothing industry is a marvel. Walk into any fashion store and you have your pick of thousands of different items in a huge variety of styles. Yet the industry is also marked by its unsustainability.

Some of the most popular materials, such as polyester, are derived from petroleum. Plastic microfibres from synthetic fabrics end up in the oceans and enter our food chain. In turn, production of natural fibres such as cotton demands an enormous amount of water.

The very nature of fashion encourages people to toss their old clothes in landfills and buy the next popular thing. It is a monumental problem, but people are now aware of it.

Gown made of birch

Churn after reading: Helsingin Sanomat, Finland’s most widely read newspaper, can become fabric for a laptop sleeve with Ioncell’s process, which dissolves cellulose and turns it into fibres.Photo: Eeva Suorlahti

“Sustainability is becoming very important to the consumer today,” says Anna-Kaisa Auvinen, managing director of Finnish Textile and Fashion, a textile and clothing industry organisation.

“In Finland we have great fibre innovations that will help the industry be more environmentally friendly. Increasingly we see new startups being formed in Finland with corporate social responsibility as the core of the company.”

Several Finnish organisations have been puzzling over the issue of a sustainable raw material for textiles for years, including VTT Technical Research Centre of Finland and Aalto University. Pirjo Kääriäinen, professor of design-driven fibre innovation at Aalto, estimates that seven or eight different projects are currently under way, and some of them have graduated out of the laboratory.

At Aalto University, professor Pirjo Kääriäinen and scientist Michael Hummel show how they and their students make wood into thread and fabric without producing waste or consuming chemicals.

Video: Ioncell/Aalto University

Kääriäinen is involved in Ioncell, a project that has developed a method of creating high-quality textile fibres from wood or recycled materials.

They found the perfect publicity for their product when Jenni Haukio, the First Lady of Finland, wore a dress made from birch-based Ioncell fibre to the annual Independence Day gala.

Infinite source of raw materials

Aalto University students Simone Haslinger and Yingfeng Wang produced a scarf using Ioncell fibres recycled from old cotton; French President Emmanuel Macron received it as a gift when he visited the school.Photo: Mikko Raskinen

“Traditional methods of creating fibre from cellulose, like rayon, require heavy chemicals,” Kääriäinen says. “The whole Ioncell production process is safe and non-harmful. It can even keep the colour: if you recycle red T-shirts you can get red fibres out of the process without needing to re-dye it.”

Another company active in the field is Infinited Fiber. Its roots date back to the 1980s, when various Finnish corporations and VTT studied viscose production.

“The breakthrough came in about 2010, when we discovered how to use waste paper as a raw material,” says CEO Petri Alava. “We can now use a huge variety of raw materials, like paper, carboard or textile waste. Availability is a big issue for the industry, but some of the infrastructure is already in place for these materials, like cardboard.”

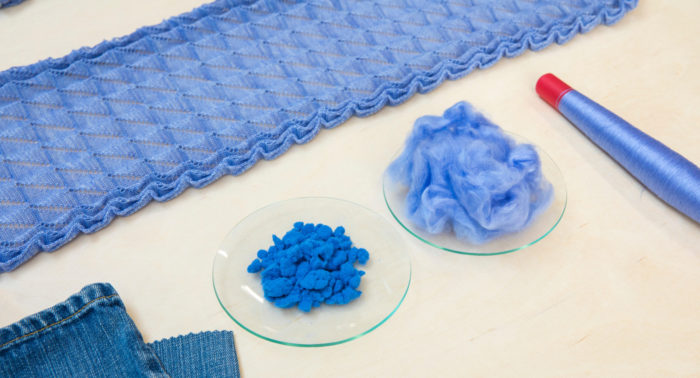

Infinited Fiber was spun off from VTT in 2015 and now has a pilot plant in operation. Their process separates fibre, turns it into a liquid, and transforms the liquid into a new cotton-like fibre. Cotton is a major material for the mainstream textile market, and Infinited Fiber plans to license their technology to big global producers. Their denim has already met 100 percent of commercial quality requirements.

“It’s encouraging to see the high interest we are receiving from the market,” Alava says. “The younger generation wants environmentally sustainable clothing, and this is a major challenge for fashion brands.”

Spin to win

Companies such as the Finnish brand Melli EcoDesign are trying Spinnova fabrics. Melli is particularly interested in textile textures, since it specialises in clothing for infants and premature babies.Photo: Spinnova

Spinnova is located in the central Finnish city of Jyväskylä, at the heart of Finnish forest country. They use wood pulp as their raw material, but their process has a different spin.

“We use no harmful chemicals at all,” says CEO Janne Poranen. “We use a mechanical process to spin the natural fibres through small nozzles to create textile filaments.”

The only by-product of Spinnova’s technology is water that evaporates during drying and is reused in the spinning process. The closed-loop system caught the attention of Finnish fashion icon Marimekko and a partnership began. At the time of writing, the two companies are planning to bring their product to customers in the near future.

“Our pilot plant is in the startup phase and then we will begin to scale up,” Poranen says. “In two or three years we expect to see big volumes.”

Finnish innovators such as Spinnova, Ioncell and Infinited Fiber have a huge goal: to find a sustainable process with sustainable materials for the world’s textile needs. They employ different methods, but there’s more than one way to stride down a catwalk.

By David J. Cord, March 2019